The ZF 6HP19 and 6HP21 Generation 2 transmissions are advanced 6-speed automatic units designed for fuel efficiency and smooth shifting. They feature innovative solenoid systems, integral to modern vehicle performance and reliability.

1.1 Overview of ZF 6HP19 and 6HP21 Transmissions

The ZF 6HP19 and 6HP21 Generation 2 transmissions are advanced 6-speed automatic units designed for optimal performance, fuel efficiency, and smooth gear shifting. These transmissions are widely used in various vehicle types, from sedans to SUVs, due to their versatility and reliability. The ZF 6HP19 is compact and lightweight, making it ideal for smaller vehicles, while the ZF 6HP21 is slightly larger and heavier, catering to vehicles with higher torque requirements. Both models feature cutting-edge technology, including advanced solenoid systems, adaptive shifting algorithms, and robust torque converter designs. The Generation 2 updates introduced improved hydraulic controls, enhanced clutchpack durability, and better thermal management, ensuring superior performance under varying driving conditions. These transmissions are renowned for their seamless gear transitions, responsive acceleration, and ability to adapt to driver behavior, making them a preferred choice in modern automotive engineering.

1.2 Features and Importance in Modern Vehicles

The ZF 6HP19 and 6HP21 Generation 2 transmissions are integral to modern vehicles, offering exceptional performance, fuel efficiency, and reliability. Key features include their 6-speed automatic design, adaptive shifting technology, and lightweight construction. These transmissions excel in providing smooth gear transitions and responsive acceleration, making them ideal for a wide range of vehicles. The compact design of the 6HP19 and the slightly larger 6HP21 cater to varying torque requirements, ensuring versatility across vehicle types. Advanced solenoid systems enable precise control over transmission fluid flow, optimizing gear shifts and torque converter lockup. These features contribute to improved fuel economy, reduced emissions, and enhanced driver comfort. Their importance lies in meeting modern demands for efficiency and performance, while also supporting advanced driver assistance systems. The transmissions’ modular architecture and robust engineering ensure durability and adaptability, solidifying their role as critical components in contemporary automotive technology.

Understanding Solenoids in Automatic Transmissions

Solenoids are electronic components that control the flow of transmission fluid in automatic transmissions. They act as switches, enabling precise gear shifts and torque converter lockup, ensuring smooth and efficient operation.

2.1 What Are Solenoids?

Solenoids are electromagnetic devices that act as electronic switches in automatic transmissions. They control the flow of transmission fluid by opening or closing valves in response to electrical signals from the vehicle’s ECU. These signals dictate gear shifts, torque converter lockup, and pressure regulation. Solenoids are crucial for precise control over transmission operations, enabling smooth and efficient gear changes. Unlike older hydraulic systems, solenoids provide faster and more accurate responses, making them essential in modern transmissions like the ZF 6HP19 and 6HP21. Each solenoid is designed to perform specific functions, such as controlling clutch packs or regulating pressure. They are integral to the solenoid diagram, which maps their layout and connections for diagnostic and repair purposes. Understanding solenoids is fundamental for maintaining and troubleshooting advanced transmission systems, as they directly impact vehicle performance and reliability.

2.2 Role of Solenoids in Transmission Operation

Solenoids play a vital role in the operation of ZF 6HP19 and 6HP21 transmissions by controlling the flow of transmission fluid. They act as electronic valves, directing fluid to specific clutch packs and bands to engage or disengage gears. This precise control enables smooth and seamless gear shifts, ensuring optimal vehicle performance. Solenoids also regulate torque converter lockup, enhancing fuel efficiency and reducing wear on transmission components. By receiving electrical signals from the ECU, solenoids execute commands to adjust pressure and fluid flow, ensuring proper gear engagement and disengagement. Their operation is critical for maintaining the transmission’s adaptive shifting capabilities, allowing the system to respond to driving conditions effectively. Solenoids are integral to the transmission’s hydraulic control system, making them essential for its overall functionality and efficiency. Their proper function ensures smooth acceleration, responsive shifting, and reliable operation under various driving conditions.

2.3 Types of Solenoids in ZF Transmissions

In ZF 6HP19 and 6HP21 transmissions, multiple solenoids work together to control various aspects of transmission operation. These include the Electronic Pressure Control Solenoid, which regulates transmission fluid pressure, and the Shift Solenoids A and B, responsible for controlling gear shifts by activating specific clutches and bands. Additionally, the Torque Converter Solenoid manages the lock-up clutch, enhancing fuel efficiency by directly connecting the engine to the transmission. Each solenoid has a distinct role, ensuring precise control over fluid flow, pressure, and gear engagement. The solenoid diagram provides a detailed layout of these components, aiding in diagnostics and repairs. Understanding the types and functions of these solenoids is crucial for maintaining optimal transmission performance and addressing potential issues effectively. Proper functioning of these solenoids ensures smooth shifting, efficient operation, and longevity of the transmission system.

Importance of the Solenoid Diagram

The solenoid diagram is essential for understanding the layout and function of solenoids in ZF 6HP19/6HP21 transmissions. It aids in diagnosing issues, planning repairs, and ensuring smooth transmission operation, making it a crucial tool for technicians and enthusiasts alike.

3.1 Why the Solenoid Diagram is Essential

The solenoid diagram is indispensable for anyone working with ZF 6HP19 and 6HP21 transmissions. It provides a detailed visual representation of the solenoid layout, electrical connections, and functions, enabling precise diagnostics and repairs. By understanding this diagram, technicians can identify faulty solenoids or wiring issues efficiently. It simplifies troubleshooting by mapping out how each solenoid interacts within the transmission system. This visual guide is also a valuable educational tool, helping enthusiasts and professionals alike gain insights into the complex operation of modern automatic transmissions. Without the solenoid diagram, pinpointing specific issues would be challenging, leading to prolonged repair times and potential misdiagnoses. Thus, it is a cornerstone resource for maintaining and optimizing the performance of these advanced transmissions.

3.2 Applications in Diagnostics and Repairs

The solenoid diagram serves as a vital tool in diagnosing and repairing issues within the ZF 6HP19 and 6HP21 transmissions. By providing a clear map of solenoid locations, wiring connections, and their respective functions, the diagram enables technicians to pinpoint faults quickly. It aids in identifying electrical issues, such as failed solenoids or damaged wiring, and mechanical problems like internal wear or fluid blockages. During repairs, the diagram guides the replacement of faulty components, ensuring accuracy and efficiency. It also helps in understanding how solenoids interact with the transmission’s electronic control system, making it easier to address complex issues. For both professionals and DIY enthusiasts, the solenoid diagram simplifies the troubleshooting process, reducing guesswork and potential errors. This resource is indispensable for maintaining the optimal performance of these advanced transmissions, ensuring precise and effective diagnostics and repairs.

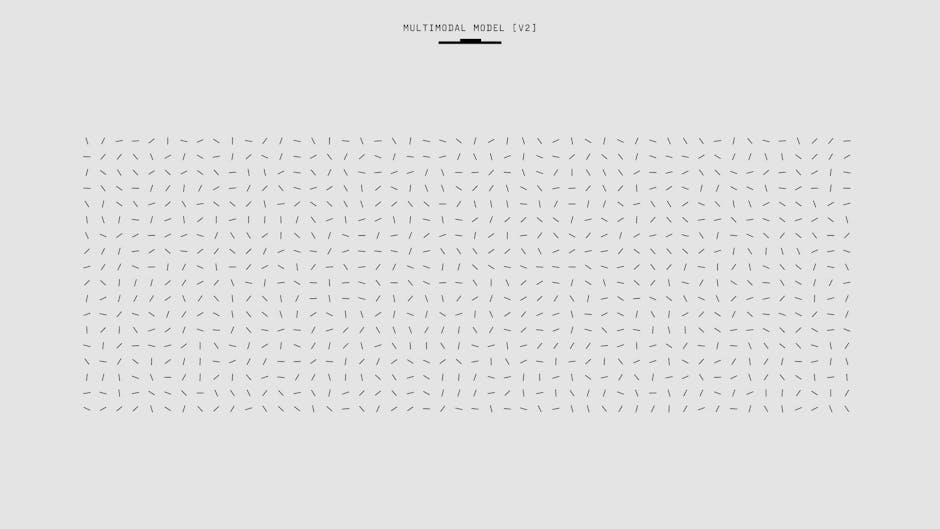

Solenoid Diagram Breakdown

The ZF 6HP19/6HP21 Generation 2 solenoid diagram provides a detailed layout of solenoid positions, wiring connections, and functional roles. It helps users interpret how solenoids interact within the transmission system for effective diagnostics and troubleshooting.

4.1 Layout and Key Components

The ZF 6HP19 and 6HP21 Generation 2 solenoid diagram provides a clear visual representation of the solenoid system’s arrangement and functionality. The layout is organized to show the positions of each solenoid within the transmission, along with their respective wiring connections. Key components include the solenoid pack, which houses multiple solenoids responsible for controlling fluid pressure and gear actuation. The diagram also highlights the electrical connectors and wiring harnesses that link the solenoids to the transmission control module (TCM). Each solenoid is labeled according to its function, such as clutch control, pressure regulation, or torque converter lockup. The diagram’s color-coded wires and symbols simplify identification and troubleshooting; Additionally, the layout illustrates the integration of the solenoid system with the valve body and clutch packs, providing a comprehensive view of how these components interact to ensure smooth gear shifts and efficient transmission operation. This detailed breakdown is essential for diagnosing and repairing solenoid-related issues.

4.2 Understanding the Diagram’s Symbols and Notations

The ZF 6HP19 and 6HP21 Generation 2 solenoid diagram employs standardized symbols and notations to represent various components and their connections. Solenoids are typically depicted as rectangular or circular shapes, labeled with their respective functions, such as “Clutch Control” or “Pressure Regulation.” Electrical connections are shown as lines with arrows, indicating the flow of current. Color-coded wires are used to differentiate between solenoids, making it easier to trace wiring paths. The diagram also includes symbols for electrical connectors, relays, and sensors, which are crucial for diagnosing issues. Notations such as “ECU” or “TCM” refer to the transmission control module and engine control unit, highlighting their role in solenoid activation. Additional symbols may represent fluid flow, pressure points, or mechanical linkages within the transmission; A reference key or legend is often provided to decode these symbols, ensuring clarity for technicians and enthusiasts. Understanding these visual elements is key to interpreting the diagram effectively and performing accurate repairs.

4.3 How to Read the Solenoid Diagram Effectively

Reading the ZF 6HP19 and 6HP21 Generation 2 solenoid diagram requires a systematic approach to interpret its symbols, layout, and connections accurately. Begin by identifying the overall structure, noting how solenoids are arranged within the transmission. Typically, solenoids are represented by distinct shapes or colors, with labels indicating their functions, such as “Clutch Control” or “Pressure Regulation.” Locate the legend or key provided with the diagram to decode these symbols and understand their roles.

Next, trace the electrical connections, often depicted as lines with arrows, indicating the flow of current from the ECU to each solenoid. Color-coded wires may differentiate between solenoids, aiding in tracing wiring paths. Identify connectors, relays, and sensors, as they are critical for diagnosing electrical issues.

For effective troubleshooting, cross-reference symptoms like slipping or erratic shifting with the diagram. For instance, if slipping occurs, focus on solenoids controlling clutch packs. Use tools like a multimeter to check electrical resistance or a scan tool to monitor solenoid activation in real-time. Combine diagram insights with these tools for precise diagnostics.

By understanding the symbols, layout, and connections, and applying this knowledge, you can diagnose and repair issues efficiently. Practice and familiarity with the diagram will enhance your ability to maintain or repair these advanced transmissions effectively.

Common Issues and Troubleshooting

Common issues include electrical failures, mechanical wear, and fluid blockages. Troubleshooting involves using diagnostic scanners, inspecting wiring, and checking solenoid activation to identify and resolve malfunctions efficiently.

5.1 Symptoms of Solenoid Malfunction

Common symptoms of solenoid malfunction in ZF 6HP19 and 6HP21 transmissions include erratic shifting, delayed engagement, and transmission slipping. Drivers may experience rough or jerky gear changes, hesitation during acceleration, or failure to shift into higher gears. Another noticeable symptom is the illumination of the “Check Engine” or transmission warning light on the dashboard, indicating an issue within the system. In some cases, the vehicle may enter “limp mode” to protect the transmission, severely limiting performance. These symptoms often arise from electrical failures, such as wiring issues or solenoid shorts, or mechanical wear within the solenoid itself. Additionally, fluid blockages or debris buildup can disrupt solenoid function, leading to inconsistent transmission behavior. Recognizing these signs early is crucial for preventing further damage and ensuring timely repairs. The solenoid diagram PDF is essential for diagnosing these issues accurately, as it provides a detailed map of the solenoid layout and connections, aiding in identifying faulty components.

5.2 Diagnostic Steps and Tools

Diagnosing solenoid issues in ZF 6HP19 and 6HP21 transmissions involves a systematic approach using specialized tools. Begin by connecting an OBD-II scanner to retrieve any error codes stored in the vehicle’s ECU, which can pinpoint specific solenoid-related faults. Next, perform a visual inspection of the solenoid wiring harness and connectors to identify any signs of damage, corrosion, or loose connections. Utilize a multimeter to test solenoid resistance and ensure proper electrical connectivity. The ZF 6HP19/6HP21 Generation 2 solenoid diagram PDF is invaluable for mapping solenoid locations and wiring circuits, aiding in targeted diagnostics. Additionally, scan tools like those from Ross-Tech or similar software can provide real-time data on solenoid performance and transmission operation. By combining these tools and steps, technicians can accurately identify faulty solenoids or related components, ensuring precise repairs and restoring optimal transmission functionality. Regular use of these diagnostic methods helps prevent prolonged damage and maintains the transmission’s efficiency and reliability.

5.3 Case Studies of Common Solenoid Issues

Several common solenoid-related issues have been documented in ZF 6HP19 and 6HP21 transmissions. One case involved a vehicle experiencing erratic shifting patterns due to a faulty torque converter solenoid. The solenoid diagram PDF revealed improper wiring connections, which were promptly repaired. Another case highlighted a mechanical failure in the EDS solenoid, causing delayed gear engagement. By referencing the diagram, technicians identified excessive wear on the solenoid’s internal components and replaced it. A third case involved fluid contamination blocking solenoid operation, leading to transmission slipping. Cleaning the solenoid and replacing the fluid resolved the issue. These case studies demonstrate how the solenoid diagram PDF aids in diagnosing and resolving common problems effectively. By analyzing these real-world scenarios, technicians can better understand solenoid behavior and apply targeted repairs, ensuring optimal transmission performance and longevity. These examples underscore the importance of regular maintenance and proactive troubleshooting.

Repair and Replacement Guide

The ZF 6HP19/6HP21 Generation 2 solenoid diagram PDF guides technicians through solenoid replacement. Access the transmission, identify faulty solenoids using the diagram, and replace them with new units, ensuring proper wiring and fluid levels.

6.1 Steps to Replace a Faulty Solenoid

To replace a faulty solenoid in the ZF 6HP19 or 6HP21 Generation 2 transmission, follow these steps:

- Lift and secure the vehicle to access the transmission pan.

- Drain the transmission fluid and remove the pan to expose the solenoid pack.

- Use the solenoid diagram to identify the faulty solenoid’s location and wiring connections.

- Disconnect the electrical connector and remove the faulty solenoid from its housing.

- Install the new solenoid, ensuring it is securely fastened and properly seated.

- Reconnect the electrical connector and replace the transmission pan.

- Refill the transmission with the recommended fluid level.

- Test the transmission’s operation to ensure smooth shifting and proper function.

Consult the ZF 6HP19/6HP21 Generation 2 solenoid diagram PDF for detailed visual guidance during the replacement process.

6;2 Tools and Materials Needed

To replace a faulty solenoid in the ZF 6HP19 or 6HP21 Generation 2 transmission, you will need specific tools and materials to ensure the job is done correctly and efficiently.

- A socket set or wrench set for removing bolts and fasteners.

- Torque wrench for precise tightening of components.

- A drain pan to collect transmission fluid during the replacement process.

- New transmission fluid to refill the system after repairs.

- A replacement solenoid compatible with the ZF 6HP19/6HP21 Generation 2 transmission.

- Electrical connectors and wiring tools for disconnecting and reconnecting the solenoid.

- A clean, lint-free cloth for cleaning surfaces and components.

- A copy of the ZF 6HP19/6HP21 Generation 2 solenoid diagram PDF for reference.

Having these tools and materials ready will ensure a smooth and successful solenoid replacement process. Refer to the solenoid diagram for specific locations and connections to avoid errors;

6.3 Best Practices for Solenoid Replacement

When replacing a solenoid in the ZF 6HP19 or 6HP21 Generation 2 transmission, adhering to best practices ensures a successful repair and maintains system integrity.

- Always start by disconnecting the battery to prevent electrical shocks or accidental engagement of the transmission.

- Refer to the ZF 6HP19/6HP21 Generation 2 solenoid diagram PDF for accurate solenoid locations and wiring connections.

- Drain transmission fluid carefully using a pan and proper tools to avoid spillage and environmental contamination.

- Inspect and clean all connectors and surfaces before installing the new solenoid to ensure proper electrical and mechanical connections.

- Tighten all bolts and fasteners to the manufacturer’s specified torque values to prevent damage or leaks.

- After installation, refill the transmission with the recommended fluid level and type to ensure optimal performance.

- Test the transmission thoroughly by running through all gears to check for smooth operation and proper solenoid function.

Following these best practices minimizes the risk of complications and ensures the longevity and reliability of the transmission system.

Preventative Maintenance

Regular fluid checks, inspections, and referencing the ZF 6HP19/6HP21 Generation 2 solenoid diagram ensure optimal transmission health. Schedule routine maintenance to detect early issues and maintain solenoid functionality, preventing costly repairs.

7.1 Tips for Maintaining Transmission Health

Regular maintenance is crucial for ensuring the longevity and performance of your ZF 6HP19 or 6HP21 Generation 2 transmission. Start by checking the transmission fluid level regularly, as low or degraded fluid can lead to solenoid and clutch pack issues. Use the specified ATF (Automatic Transmission Fluid) recommended by the manufacturer to maintain optimal lubrication and hydraulic pressure. Additionally, inspect the transmission filter and replace it as needed to prevent debris from clogging the system. Referencing the ZF 6HP19/6HP21 Generation 2 solenoid diagram can help identify potential issues early, such as wiring faults or solenoid malfunctions. Avoid extreme driving conditions, like rapid acceleration or towing heavy loads, which can strain the transmission. Keep the transmission cool by ensuring proper airflow around the pan and cooler lines. Lastly, address any unusual symptoms, such as slipping or erratic shifting, promptly to prevent further damage. By following these tips, you can ensure your transmission operates smoothly and reliably for years to come.

7.2 Regular Checks to Prevent Solenoid Issues

Regular checks are essential to prevent solenoid-related issues in your ZF 6HP19 or 6HP21 Generation 2 transmission. Begin by using a diagnostic scanner to monitor the transmission control module (TCM) for any error codes, which can indicate solenoid malfunctions. Inspect the solenoid wiring harness and connectors for signs of wear, corrosion, or loose connections, as these can disrupt electrical signals. Refer to the ZF 6HP19/6HP21 Generation 2 solenoid diagram to locate and visually examine each solenoid for leaks or physical damage. Test solenoid resistance using an ohmmeter to ensure they fall within the manufacturer’s specifications. Additionally, check the transmission fluid level and condition, as dirty or degraded fluid can interfere with solenoid operation. Perform these checks during routine maintenance to identify and address potential issues before they escalate. Regular inspections, combined with timely repairs, can significantly extend the lifespan of your transmission’s solenoid system and maintain optimal performance.

7.3 Fluid Maintenance and Its Impact on Solenoids

Fluid maintenance is critical for the optimal performance and longevity of the ZF 6HP19 and 6HP21 Generation 2 solenoids. Transmission fluid lubricates and cools the solenoids, ensuring smooth operation and preventing overheating. Using the incorrect fluid type or allowing the fluid to degrade can lead to solenoid malfunction, erratic shifting, and reduced transmission efficiency. Regular fluid checks should be performed to ensure the fluid level is within the recommended range and that it is free from contamination. Refer to the ZF 6HP19/6HP21 Generation 2 solenoid diagram for specific fluid specifications and recommendations. Replace the transmission filter and flush the system as outlined in the manufacturer’s schedule to maintain fluid quality. Neglecting fluid maintenance can result in solenoid failure, requiring costly repairs. By prioritizing fluid care, you can protect the solenoids and ensure reliable transmission performance over time.

The ZF 6HP19/6HP21 Generation 2 solenoid diagram is essential for diagnostics and repairs. It aids in understanding solenoid functions, ensuring smooth transmission operation. For further learning, refer to ZF’s official resources and technical guides.

8.1 Summary of Key Points

The ZF 6HP19 and 6HP21 Generation 2 transmissions are advanced automatic units with solenoid systems critical for smooth operation. The solenoid diagram PDF is essential for understanding layout, function, and diagnostics. It aids in identifying faulty solenoids, wiring issues, or mechanical failures, enabling precise repairs; Regular maintenance, such as fluid checks and electrical inspections, prevents common issues like erratic shifting or transmission slipping. The diagram is a vital resource for technicians and enthusiasts, providing a visual guide for troubleshooting and solenoid replacement. By mastering this tool, one can ensure optimal transmission performance, address problems early, and extend the system’s lifespan; For further learning, ZF’s official resources and technical guides offer in-depth insights into these sophisticated transmissions.

8.2 Additional Resources for Further Learning

For deeper understanding and practical application, several resources are available to complement the ZF 6HP19 and 6HP21 Generation 2 solenoid diagram PDF. Official ZF technical manuals and service guides provide detailed insights into transmission architecture and solenoid functionality. Reputable automotive forums and transmission specialist websites offer real-world experiences and troubleshooting tips from professionals and enthusiasts. Additionally, diagnostic tools like OBD-II scanners and transmission-specific software can enhance your ability to interpret solenoid performance and error codes. Video tutorials on platforms like YouTube often demonstrate solenoid replacement and system diagnostics step-by-step. For advanced learners, courses on automatic transmission systems from automotive training institutes can provide a comprehensive education. These resources collectively empower technicians and enthusiasts to master the intricacies of ZF transmissions and solenoid systems, ensuring efficient repairs and maintenance.